Door {0}

Door {0}

Testing instruments (5)

Testing instruments (5) Total trading staff (2)

Total trading staff (2) Total floorspace (6,619㎡)

Total floorspace (6,619㎡) Years in industry(7)

Years in industry(7)

ABOUT US

ABOUT US .

.- www.fkdmg.com

- www.fkdmg.com

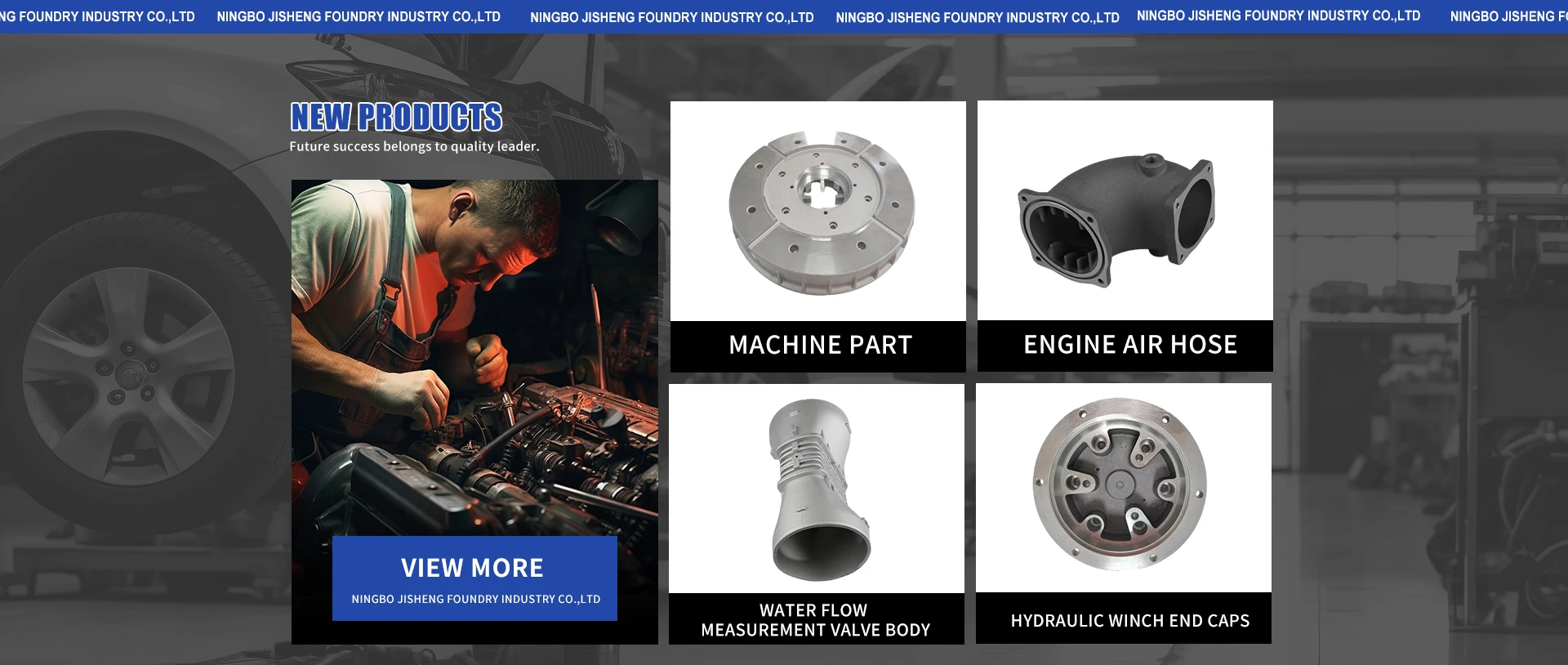

Aluminium alloy casting products

Casting parts refer to metal parts manufactured by casting technology. They have the advantages of reliable quality, compact structure, high processing accuracy, flexible molding, and low cost. They are indispensable and important components in various mechanical equipment. This article will introduce the advantages and characteristics of castings in detail to better understand the advantages of castings.

Advantages of castings

(1)Reliable quality: During the casting process of castings, molten metal can completely fill the mold, making the internal structure of the parts more compact and uniform, making the quality of the parts more reliable.

(2)Compact structure: The casting has a compact structure, which can meet certain mechanical strength requirements, has high rigidity, good wear resistance, and can resist external forces such as vibration and impact.

(3)High processing accuracy: The processing accuracy of castings is high, which can meet certain dimensional accuracy requirements, the dimensional accuracy requirements of parts, and the installation accuracy requirements of parts.

(4)Flexible molding: The molding of castings is flexible, complex parts can be manufactured, complex geometric shapes can be manufactured, and different part design requirements can be met.

(5) Low cost: Casting parts are low in cost and can meet mass production, which can save production costs and improve the economic benefits of enterprises.

Intertek

Intertek Geverifieerd onsite door toonaangevende inspectie bedrijf, INTERTEK Group

Geverifieerd onsite door toonaangevende inspectie bedrijf, INTERTEK Group